MODERN

RELIABLE

DYNAMIC

MODERN

RELIABLE

DYNAMIC

Extensive experience and top of the line tech

We are a fully modern company that produces plastic elements in northern Estonia.

Our top-flight technologies allow us to fill orders in a high-quality, reliable manner with short turnarounds. Effective and optimized management and production processes help us keep overhead low and offer clients competitive prices.

Most of our products are made of acrylic, which is used to make sale displays, interior design elements and industrial semi-finished products. We offer professional laser cutting, CNC milling, laser engraving, gluing and moulding.

Nordic Plast is the official distributor of VFK Renzel in Estonia.

Producing a wide variety of shop fittings, VKF has been operating for more than 30 years and is known for the superb design and first-class quality of its products.

Extensive experience and top of the line tech

We are a fully modern company that produces plastic elements in northern Estonia.

Our top-flight technologies allow us to fill orders in a high-quality, reliable manner with short turnarounds. Effective and optimized management and production processes help us keep overhead low and offer clients competitive prices.

Most of our products are made of acrylic, which is used to make sale displays, interior design elements and industrial semi-finished products. We offer professional laser cutting, CNC milling, laser engraving, gluing and moulding.

Nordic Plast is the official distributor of VFK Renzel in Estonia.

Producing a wide variety of shop fittings, VKF-Renzel has been operating for more than 30 years and is known for the superb design and first-class quality of its products.

Our team

Phone: +372 7997 082

Mobile: +372 51 10 996

Phone: +372 7997 083

Mobile: +372 55 625 074

Phone: +372 7997 081

Mobile: +372 5143479

Our team

Phone: +372 7997 082

Mobile: +372 51 10 996

Phone: +372 7997 083

Mobile: +372 55 625 074

Phone: +372 7997 081

Mobile: +372 5143479

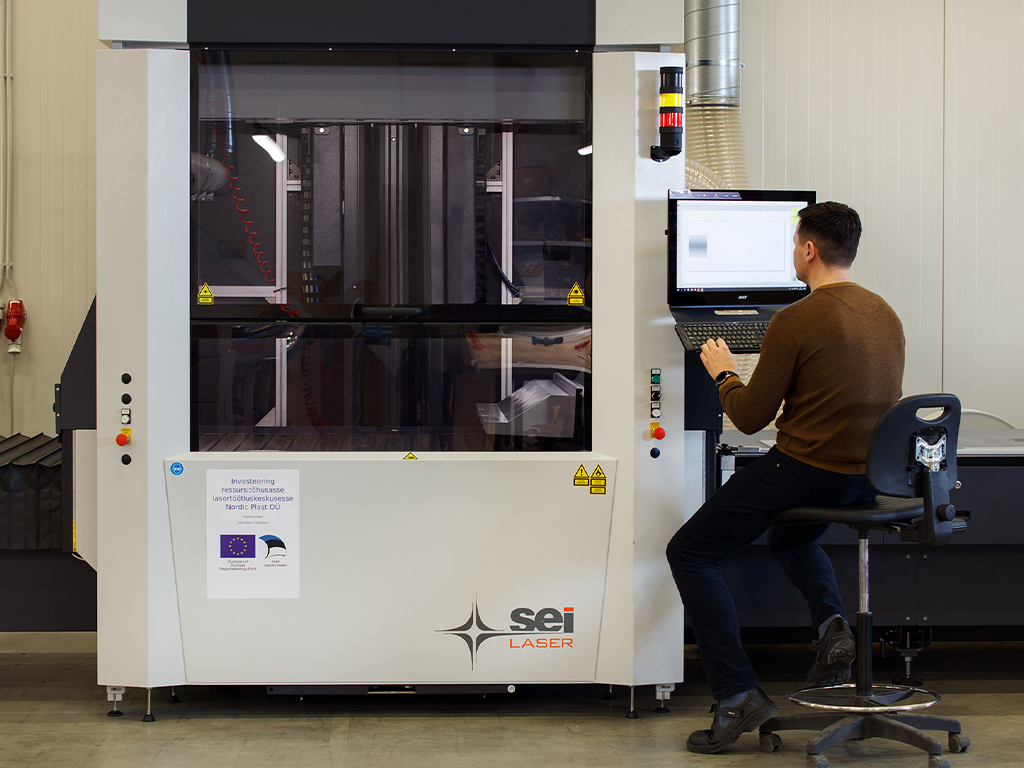

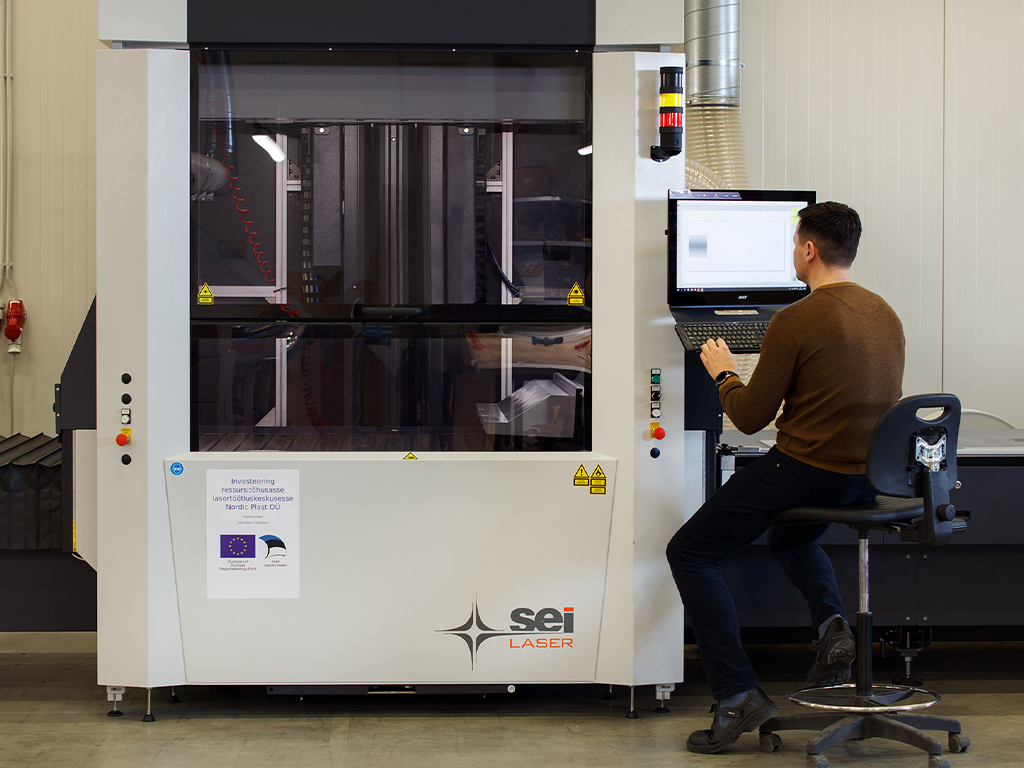

Technology

LASER CUTTING

Advanced technology allows light and fragile materials, complicated shape sand small details to be cut effectively without damaging the surface. Materials compatible with laser cutting include Plexiglas, various kinds of plastics, plywood, veneer, solid wood, cardboard, paper, paperboard, expanded plastic, textile, leather and flooring materials. The maximum area that can be laser cut is 1300×2600 mm.

LASER ENGRAVING

Laser engraving makes it possible to place a logo, trademark or product name on just as wide array of materials as with laser cutting. Our partners often use this service to brand their plastic sale or advertising displays. The maximum area that can be engraved is 1200×2500 mm and the maximum height of processed item can be up to 600 mm high.

Technology

LASER CUTTING

Advanced technology allows light and fragile materials, complicated shape sand small details to be cut effectively without damaging the surface. Materials compatible with laser cutting include Plexiglas, various kinds of plastics, plywood, veneer, solid wood, cardboard, paper, paperboard, expanded plastic, textile, leather and flooring materials. The maximum area that can be laser cut is 1300×2600 mm.

LASER ENGRAVING

Laser engraving makes it possible to place a logo, trademark or product name on just as wide array of materials as with laser cutting. Our partners often use this service to brand their plastic sale or advertising displays. The maximum area that can be engraved is 1200×2500 mm and the maximum height of processed item can be up to 600 mm high.

HOT BENDING AND MOULDING

Hot bending and moulding allows plastics with a thickness up to 10 mm to be bent with a maximum bend length of 3000 mm. Acrylic can be bent into a sharp or rounded corner with up to a 50 mm radius. Various kinds of acrylic details can also be moulded with different cooling moulds and equipment. The maximum size of acrylic sheet that can be processed is 1000×1500 mm and thickness is up to 10 mm.

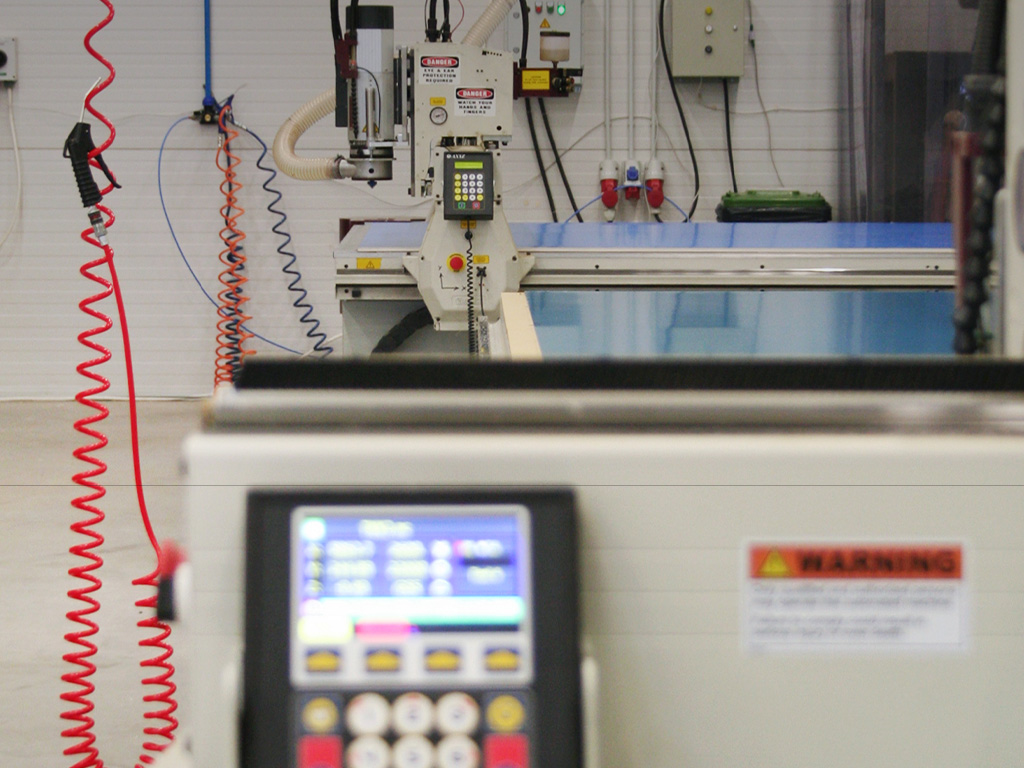

CNC MILLING

CNC milling allows corners to be cut and bumps and grooves can be levelled. The most suitable materials for CNC milling are plastics, wood, composite panels, brass and aluminium. The maximum area that can be milled is

2150×6700 mm.

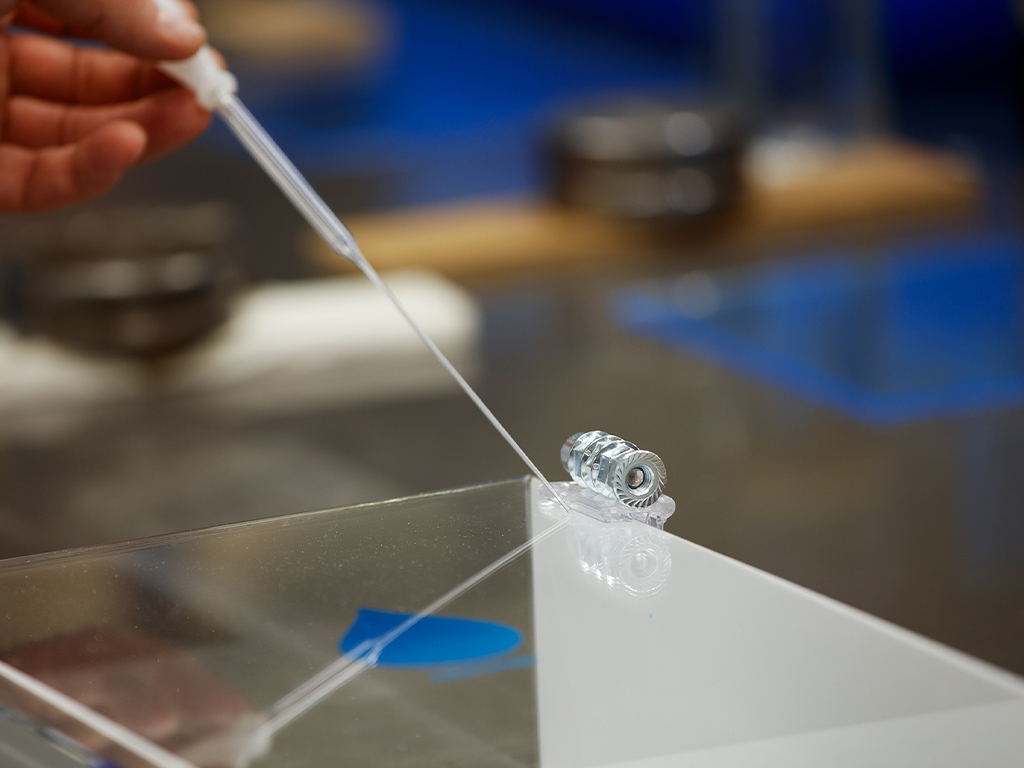

GLUING

We offer comprehensive gluing service for all the whole line of acrylic products. There is no minimum order and we can do one-off prototypes. We also have the ability to do batch gluing jobs. We offer solvent-based and UV-cured adhesives.

HOT BENDING AND MOULDING

Hot bending and moulding allows plastics with a thickness up to 10 mm to be bent with a maximum bend length of 3000 mm. Acrylic can be bent into a sharp or rounded corner with up to a 50 mm radius. Various kinds of acrylic details can also be moulded with different cooling moulds and equipment. The maximum size of acrylic sheet that can be processed is 1000×1500 mm and thickness is up to 10 mm.

CNC MILLING

CNC milling allows corners to be cut and bumps and grooves can be levelled. The most suitable materials for CNC milling are plastics, wood, composite panels, brass and aluminium. The maximum area that can be milled is

2150×6700 mm.

GLUING

We offer comprehensive gluing service for all the whole line of acrylic products. There is no minimum order and we can do one-off prototypes. We also have the ability to do batch gluing jobs. We offer solvent-based and UV-cured adhesives.

Materials

MATERIALS WE WORK

Materials can be tested free of charge to see if they can be cut.

PLASTICS

acrylic (PMMA), polycarbonate (PC), PVC, polypropylene (PP), polystyrene (PS), polyester (APET, PET-G), polyethylene (PE), polyacetate (POM) and ABS

WOOD

plywood, veneer, solid wood, HDF, MDF, melamine panel and wood chipboard

OTHER

aluminium, brass, composite panel (Dibond, Alucobond), flooring (PVC, linoleum and carpeting), cardboard, paperboard, paper, various filter materials, rubber and Teflon

Materials

MATERIALS WE WORK

Materials can be tested free of charge to see if they can be cut.

PLASTICS

acrylic (PMMA), polycarbonate (PC), PVC, polypropylene (PP), polystyrene (PS), polyester (APET, PET-G), polyethylene (PE), polyacetate (POM) and ABS

WOOD

plywood, veneer, solid wood, HDF, MDF, melamine panel and wood chipboard

OTHER

aluminium, brass, composite panel (Dibond, Alucobond), flooring (PVC, linoleum and carpeting), cardboard, paperboard, paper, various filter materials, rubber and Teflon

ENVIRONMENTAL POLICY

The mission of Nordic Plast is to generate value for clients by offering optimum plastic solutions. It’s important for us for plastic solutions to have as low an environmental impact as possible. We are constantly working to find ways for improving sorting and thereby optimizing recovery of plastic waste.

Highlights:

• we’re up to date with developments in national and international law on compounds contained in the materials we use in production;

• our plastic semi-finished products can be recovered;

• our raw ingredients meet RoHS, REACH requirements and European Chemicals Agency (ECHA) recommendations;

• we work to reduce the energy and heating expense at our company;

• we sort our plastic waste into different categories that increases the amount recycled;

• we try to use make the use of transport needed for production as clean as possible;

• we actively work to reduce the energy and material consumption in our production facilities;

• we work to prevent any pollution caused by our company.

The environment

ENVIRONMENTAL POLICY

The mission of Nordic Plast is to generate value for clients by offering optimum plastic solutions. It’s important for us for plastic solutions to have as low an environmental impact as possible. We are constantly working to find ways for improving sorting and thereby optimizing recovery of plastic waste.

Highlights:

• we’re up to date with developments in national and international law on compounds contained in the materials we use in production;

• our plastic semi-finished products can be recovered;

• our raw ingredients meet RoHS, REACH requirements and European Chemicals Agency (ECHA) recommendations;

• we work to reduce the energy and heating expense at our company;

• we sort our plastic waste into different categories that increases the amount recycled;

• we try to use make the use of transport needed for production as clean as possible;

• we actively work to reduce the energy and material consumption in our production facilities;

• we work to prevent any pollution caused by our company.